TOUGHBUILT REMOTE ASSIST SET

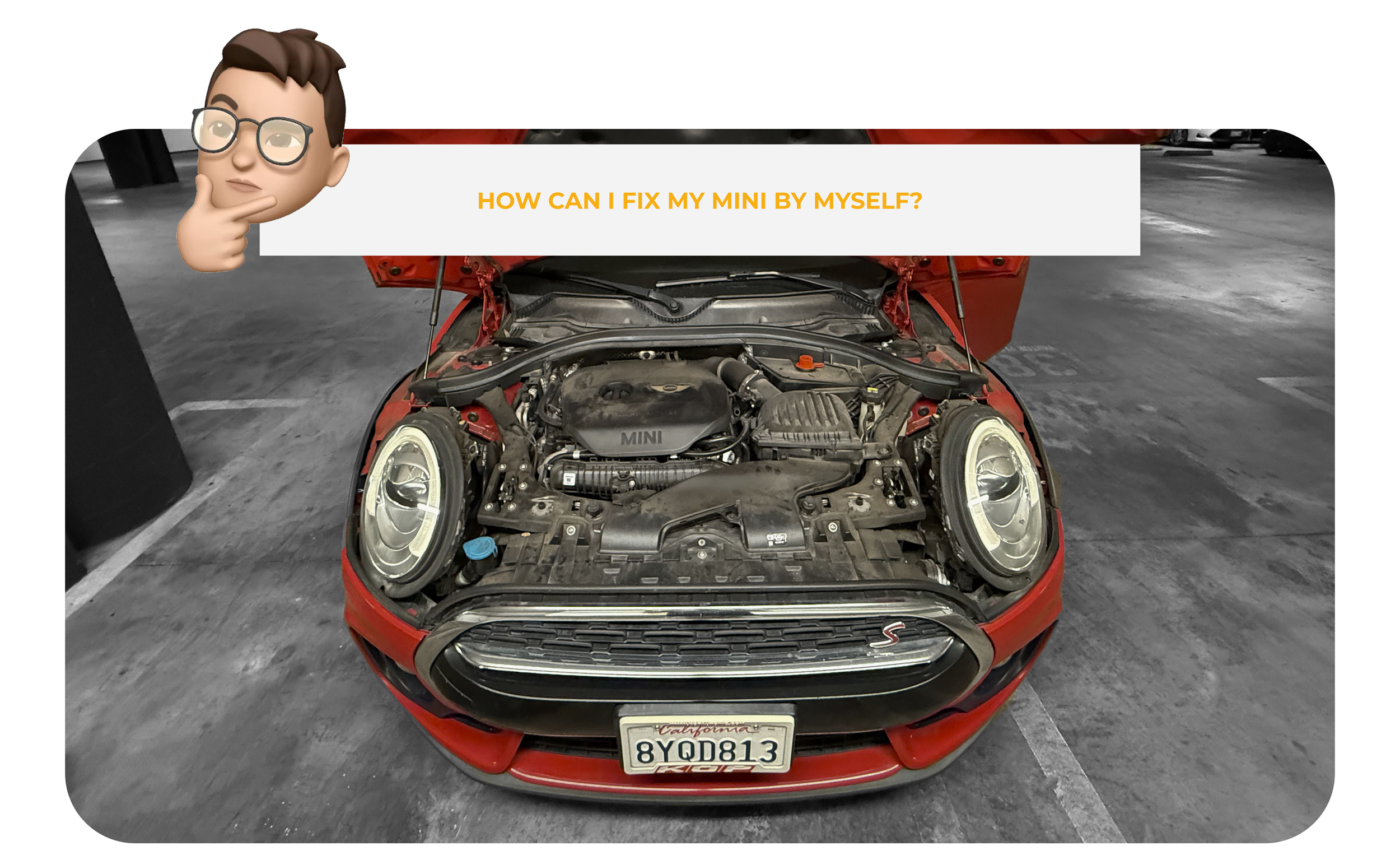

Project Intro:

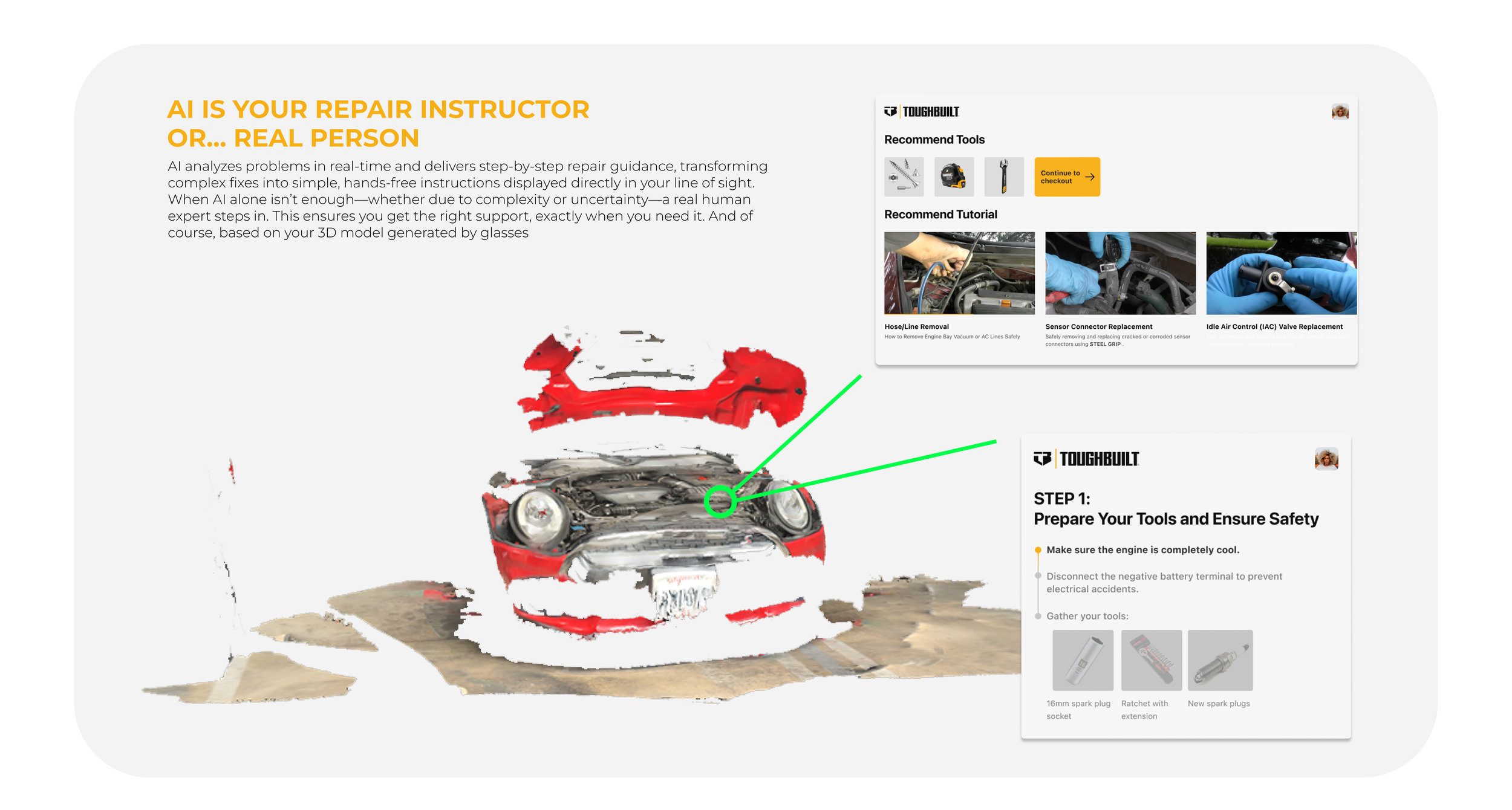

An innovative AR glasses with AI and expert remote support for maintenance, enabling users to efficiently and quickly fix faulty equipment, reduce downtime losses, and minimize reliance on external technicians.

Project Type:

Product design, High fidelity

Work time:

Jan. 2025— Apr. 2025

Team or Individual:

Individual work

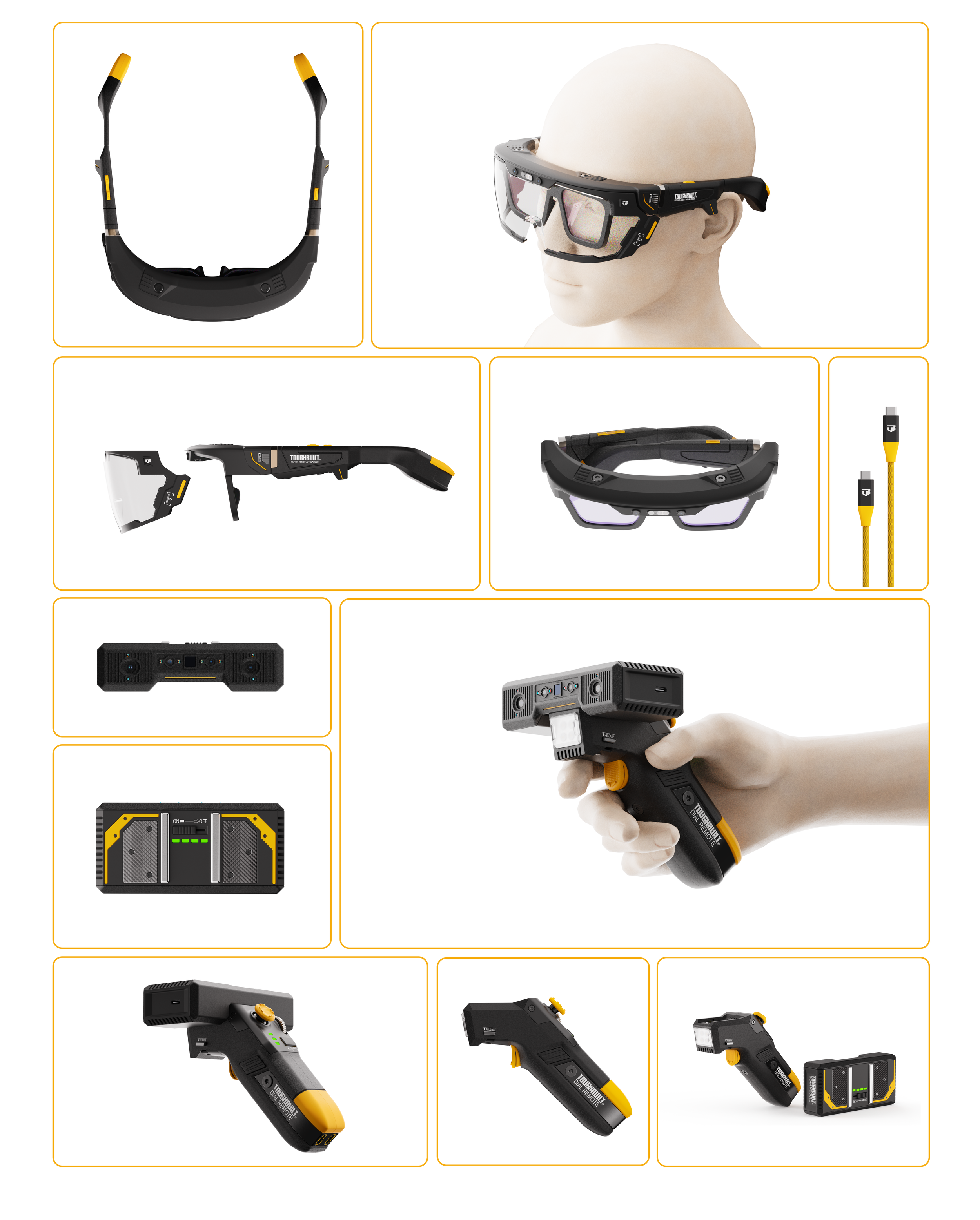

UP TO 4 HOURS

Two 1500mAh lithium batteries are embedded symmetrically in both temples of the glasses, providing up to 4 hours of continuous power.

SAFETY IS THE CORE

In industrial settings, safety isn’t just a feature—it’s a requirement. This magnetic visor enables fast, tool-free attachment, providing immediate eye and face protection in dynamic environments. Designed for both security and comfort, it ensures workers can respond quickly without sacrificing mobility or visibility—ideal for high-risk, high-speed tasks.

LIDAR, CAMERA & LED

LiDAR, camera, and LED systems work in sync to capture depth, detect context, and provide visual guidance. Together, they enable a hands-free AR experience tailored for precise diagnostics and efficient remote repair.

DEMO

DEMO

THE FACTORY SITUATION IS MORE COMPLICATED

PHYSICAL CONTROL. ENHANCED PRECISION.

In industrial settings, precision and reliability are non-negotiable—the physical remote delivers glove-friendly, tactile accuracy and faster adjustments than touchscreens alone.

A built-in flashlight switch provides quick, one-touch illumination for dark workspaces, ensuring visibility without needing a separate light source.

The joystick offers intuitive directional input for navigating menus, adjusting views, or controlling AR overlays—perfect for precision without distraction.

The remote includes its own lithium battery, offering extended runtime when connected to the glasses—keeping your system powered longer during high-demand tasks.

A tactile trigger acts as a primary action button—whether to confirm steps, capture data, or activate tools—bringing speed and familiarity to industrial workflows.

The rotary dial enables smooth parameter adjustments with high resolution, ideal for fine-tuning zoom, focus, or tool intensity

A lateral slide switch offers secure and deliberate power control, reducing accidental toggles while remaining easy to operate—even with gloves on.

WITH SCAN MODULE

The hot-shoe connector features a push-to-release mechanism, allowing for fast, tool-free attachment and removal—ideal for swapping modules or dismounting in tight spaces.

WITHOUT SCAN MODULE

MAYBE… A MORE PRECISE MODEL FOR ANNOTATION?

In industrial environments, repairs often involve complex wiring systems and tightly integrated components—far beyond what typical home repairs require. Our advanced 3D scanning captures precise geometry and spatial relationships in real time, creating high-fidelity models that support accurate annotations and targeted actions. This level of detail ensures technicians can trace, mark, and resolve issues with confidence—especially when every millimeter counts.

THREE DAYS MOKE UP

DESIGNED TO EMBODY TOUGHBUILT VALUES

Every detail in this design reflects ToughBuilt’s commitment to professionals—prioritizing durability, modularity, and hands-on efficiency. From glove-friendly controls to tool-less hot-shoe attachments, each component is built for the real world: practical, tough, and ready for work. It’s innovation that doesn’t just look good—it works hard, fits seamlessly into your gear system, and earns its place on the jobsite.